Optimization

The software allows for simulation of data (see note below), once the experimental data is described by model-free or model-based kinetics. The temperature profile can be calculated and optimized under consideration of defined boundary conditions (constant conversion rate or defined conversion values, constant signal rate, temperature range, range of heating rates). The results depend on the kind of model-free kinetics or on the kinetic model selected and its parameters. Therefore, a careful model-free or model-based analysis of the experimental data should be carried out before doing optimization. As mentioned above, the temperature program can be optimized for a constant conversion rate or constant signal rate:

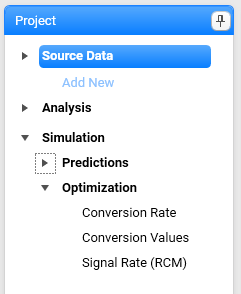

Here some tree branches (like Source Data) are collapsed for better view.

Conversion Rate: Temperature profile for a constant conversion rate.

Conversion Values: Temperature profile for defined conversion values.

Signal Rate: Temperature profile for a constant signal rate (RCM for TG, RCS for DIL).

Note

In case of projects of type DSC Curing, also calculated glass transition temperatures can be displayed as it is shown in this example.

If the Kinetics Neo project uses Additional (External) Parameter like Pressure or intensity of UV light, then the Simulation (both Prediction and Optimization) can be done for given value of additional parameter.