Optimization: Conversion Rate (including glass transition temperatures)

The aim is to simulate data exhibiting a defined constant conversion rate. For projects of type DSC Curing, the calculated glass transition temperatures can also be displayed – if Glass Transition Data was defined. The constant conversion rate can be achieved via optimization of the temperature profile where the following boundary conditions should be fulfilled:

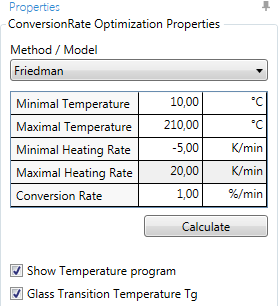

First, a Method / Model (model-free or model-based) needs to be selected (here: Friedman), where only those models are offered with which the data was already analyzed.

- The Minimal and Maximal Temperatures define the minimum and maximum temperatures of the calculations.

- Minimal and Maximal Heating Ratedefine the minimum and maximum heating rates which are allowed for the calculations.

- Conversion Rate is the target value of the conversion rate that should be kept as constant as possible during the calculations.

Default values are suggested by the software according to the experimental data.

Show Temperature program can only be activated if the X-axis unit is set to time.

Glass Transition Temperature Tg can only be activated if the X-axis unit is set to time.

Press Calculate for calculations/update of calculations.

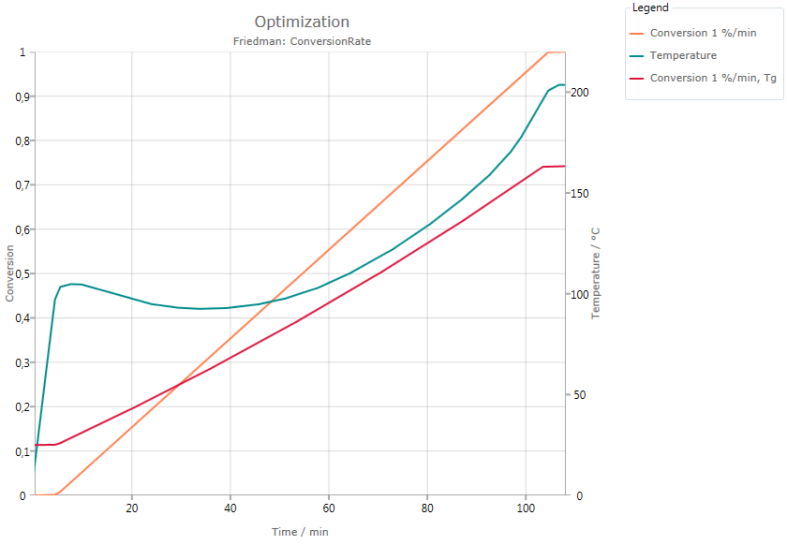

Exemplary results:

In this example, the optimized conversion curve for a constant conversion rate of 1%/min and the corresponding temperature profile as well as the calculated glass transition temperatures Tg are shown as a function of time.

Customization and exporting of the results can be done via Ribbon Toolbar.